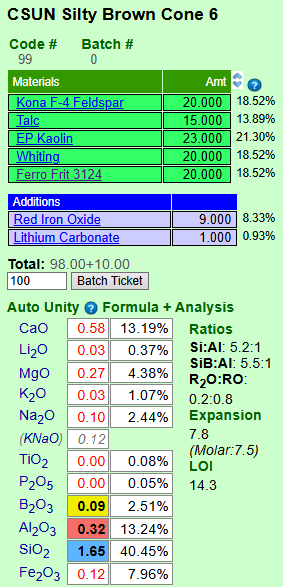

Cone 6 Sea Moss

The base formulation of this glaze began as one of my attempts of making a cone 6 clear glaze with a higher coefficient of thermal expansion (around 7.0 as calculated by Digital Fire). It wound up kind of cloudy, so instead of tossing it, I threw in some nickel and copper to see if it’d result in a nice blue/green. The result was this pretty green that breaks yellow-ish.

WARNING: this glazes runs at cone 6. The cup pictured on the left is a single dipped coat, resulting in a modestly thick coat (it also had some X’s painted over the glaze with a R.I.O. wash) . The flowy nature of the glaze creates some really lovely pooling effects where it can rest thicker, and breaks brightly over even soft edges. If you’re using groggy clay, the grog can poke through this glaze on edges, since it does get pretty thin.

I haven’t used this glaze in combination with others yet, but it has proved very consistent for me in single layers thus far.

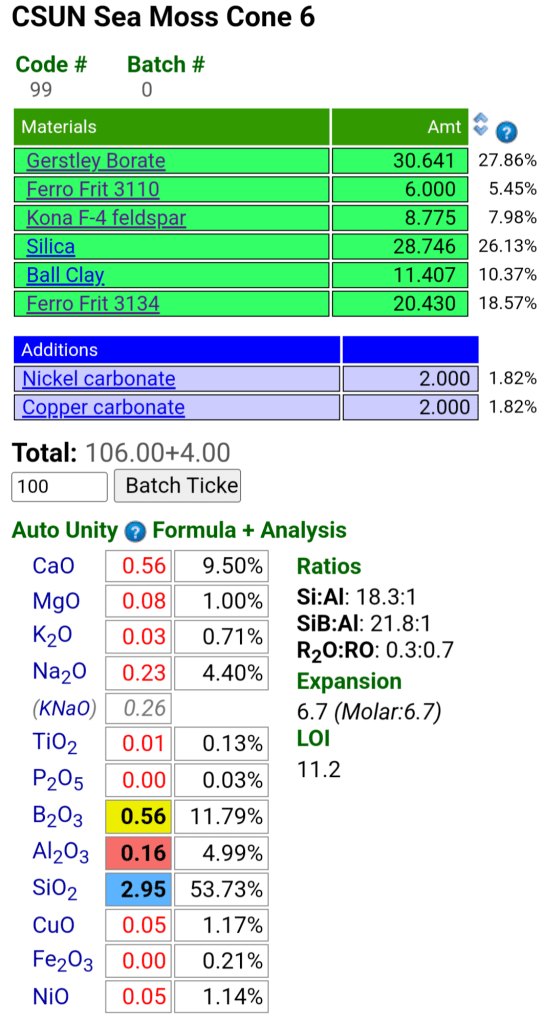

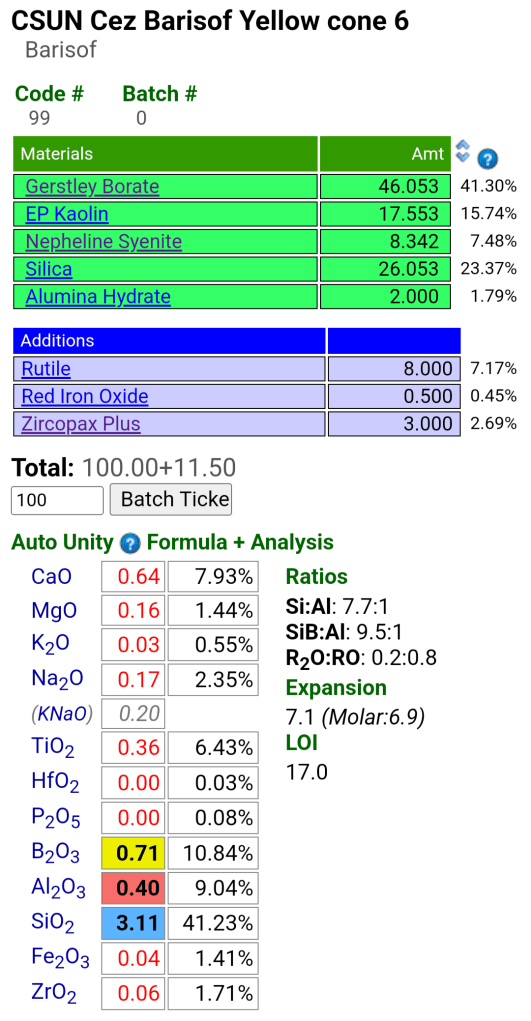

Cone 6 Barisof Yellow

This recipe is based off a cone 5 orange rutile glaze recipe that I received from Steve and Bonnie Barisof.

It’s really more orange, but I’ve already named it Barisof Yellow so I don’t want to change it.

The mug pictured has an exterior coating of Barisof Yellow, with some of it overlapping a bit of the black glaze covering the squares.

Fired at cone 6, this glaze is pretty fluid, not quite to the point of being runny, but will run with other glazes or in thick coatings.

Due to the high quantity of gerstley borate, adding sodium silicate to deflocculate the glaze is pretty necessary to avoid too much shrinkage when drying.

I really appreciate that this glaze lightens in tone as it thickens, and breaks darker where thinner. As a bonus, the rutile content makes it interact in fun ways with other glazes.

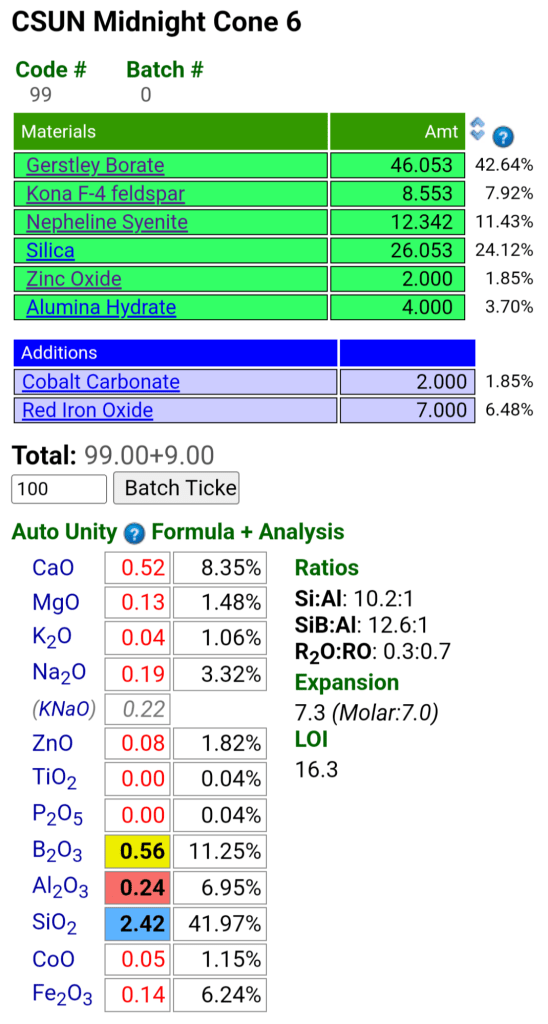

Cone 6 Midnight

This glaze is a strange one. I think of it as a clear black glaze, but it can vary a lot in its tone depending on the clay body, thickness, and firing. Often times it will come out with hues of green, somethings blue, and occasionally bits of brown come out.

It functions best on top of other glazes or as a thin-ish single layer. I’ve found that thicker coats tend to come out with a nasty pinhole here or there (without any controlled cooling or holds). On top of lighter glazes, such as my White Liner, it creates a nice cool blue color. With a rutile glaze, it creates some really fun variagation and flow, but it will run at cone 6.

Like with Barisof Yellow, adding some sodium silicate or other deflocculant to this glaze after it’s mixed helps a lot with applying it onto bisqueware. It’s definitely a more tempermental glaze, but I love its color.

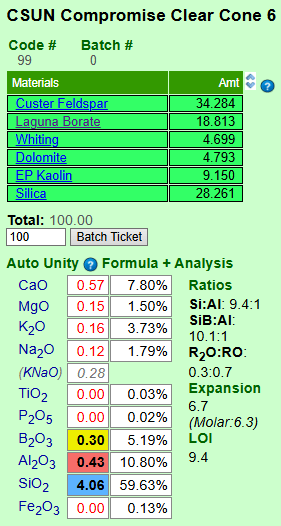

Cone 6 cOMPROMISE Clear (HE Clear)

IMAGES COMING SOON!!!

I called this compromise clear because it’s a decent clear for all the clays I’m currently using.

It’s a tweaked version of High Expansion Clear that has a bit fewer metals and a bit more alumina, silica, and boron content to keep it from devitrifying and turning matte.

It applies very nicely, and makes getting even coats pretty effortless. I’ve seen no evidence of a tendency to pinhole, and its surface is very smooth and consistent. It’s only downfall is it’s tendency to trap micro-bubbles and go a bit foggy when on darker clays or applied too thickly. It’s also susceptible to crawling when it’s applied thick.

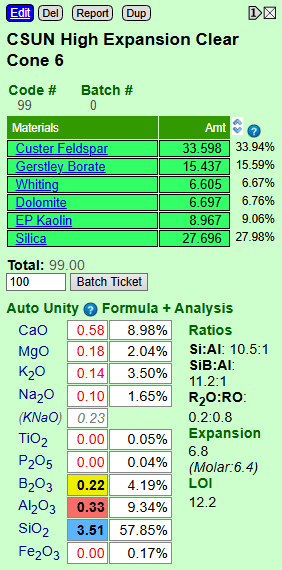

Cone 6 High-Expansion Clear

IMAGES COMING SOON!!!

This was one of my earlier clear tests that was zinc-free and had high enough thermal expansion to fit my clay bodies. Its only issue is that it tends to matte when it cools slowly. It also heals well to accommodate black clay bodies that off-gas during glaze firing. Even when more matte, the surface doesn’t cutlery mark is highly functional.

I’ve brought it back into use because its colored variations (adding 0.5% cobalt carbonate, other oxides, or 2-5% of a mason stain) play along very well underneath Compromise Clear. This way I can use variations of this glaze to add color beneath a dip into clear without causing defects or unappealing effects.

I won’t put the variations here, as they don’t add much information, and I’d encourage playing around with your own variations

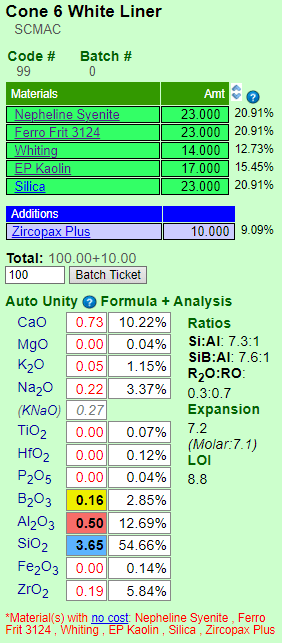

Cone 6 White Liner

I received this recipe from the kind folks at the Santa Cruz Mountain Art Center in Ben Lomand while I was doing an independent study with them in college.

It was originally formulated with 16% zircopax, but I had to switch to zircopax plus when I began my MA program at CSU Northridge. I found that 10% made for a nice substitution, and gave me a nice gloss finish that was opaque enough.

It has a relatively high expansion, but it fits my clays nicely enough. My only gripe with this recipe is that it require epsom salts to keep from hard-panning.

These two images pieces are fired in an electric kiln without controlled cooling to cone 6 in oxidation. The clay body is a Laguna Clay Company mid-fire stoneware called Elsinore buff.

I’ve also found that this glaze is pretty stable up to cone 10, but it has issues with pitting at that temperature.

Cone 6 Silty Brown

IMAGES COMING SOON!!!

This glaze is my most recent addition. I’m still figuring out the best way to apply it, but it seems to do best with a moderate single coat. It also plays nicely on top of White Liner and underneath Compromise Clear.

It can from throwing a bunch of iron oxide and a bit of lithium into a calcium matte base recipe, and seeing some really interesting yellow dust appearing. It’s kind of similar to teadust style glazes, but whatever crystals are forming are very small, hence the name silty brown.

I like the bit of natural variation this glaze brings even in cone 6 electric firings. It’s subtle, earthy, and warm.